U-PVC Window Machine

Aluminium Window Machine

Woodworking Machine

Glass Processing Machine

Steel Structure Processing Machine

Angle Tower Machine

CNC Drilling Machine

Machine Categories

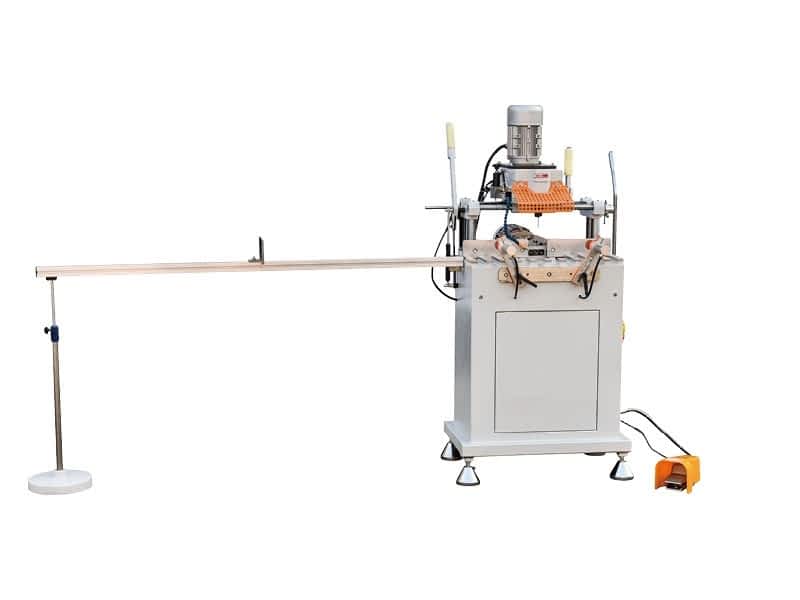

Aluminium Profile CNC Drilling Milling Machine MTE-CNC-3500MINI

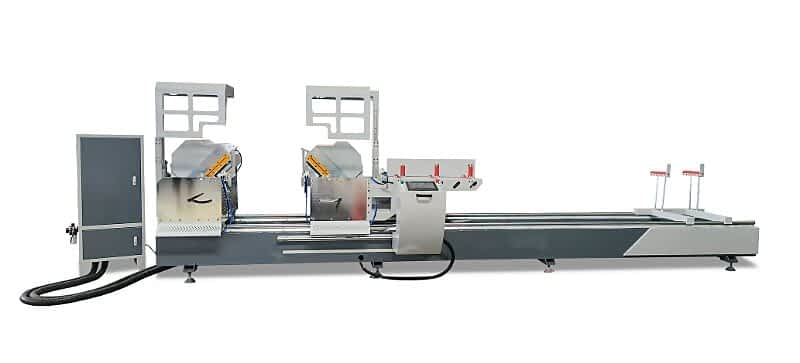

double-head CNC drilling and milling machine

3500 large automatic drilling, tapping and milling machine, the sixth generation of new models, can simultaneously realize the material drilling + tapping + milling work. The length of the machine is 4800mm, the effective processing stroke can reach 3400mm, the machine adopts heavy-duty body design, the use of international first-class brand electrical parts, pure servo motors, quiet and high-speed, the material can be realized three sides of the automatic flip, the efficiency of the work of the machine is more with the machine with the CAD guide function, greatly improve the efficiency of the work. It can be widely used for drilling and tapping and milling groove of various kinds of minimal glass doors, sliding doors and swing doors, broken bridge aluminum doors and windows, and various sizes and specifications of industrial aluminum.

This is a 3500 large-scale automatic CNC drilling and milling machine specializing in processing various aluminum materials, which has been put into the market for 7 years and is deeply trusted and praised by the majority of users. This machine is a heavy-duty machine, and the machine is designed with a heavy-duty bed, rather than an inferior light machine on the market. The machine body is designed with heavy-duty thickened steel structure, and the bed is finished by large-scale gantry boring and milling, which effectively ensures the stability and precision of the whole plate of the machine, and the machine can still maintain stability and high precision after many years of use.

All electrical components of this machine are all used first-line brands, XYZ three-axis is a pure servo motor, the machine can be kept silent when running, the maximum processing speed of this machine is as high as 20000R, which is 3-5 times that of ordinary CNC drilling and milling machine. The machine is divided into two configurations: the material can be automatically flipped on three sides and without the automatic flip function, and you can choose according to your needs. The machine is equipped with genuine CNC operating system, both of which are authoritative operating systems for drilling and milling machine tools, and the system is equipped with a multi-Chinese operation interface and one-key switching. The system has hundreds of built-in processing drawing programs, touch selection, even if the operator has no experience in using the machine tool or no education level, it can still be operated within 2 hours and proficient in application within 48 hours. When using, you only need to call the program directly according to your own workpiece requirements, such as 20 minimalist glass doors, Bologna, Weifa, laminate lights, sliding doors, swing doors, sliding doors, various keyholes, corner code holes, broken bridge doors and windows, and dozens of common patterns. In addition to the built-in drawing program of the system, the machine can also be CAD map processing, you can import the CAD drawing path or the path saved by the order splitting software directly into the machine through the USB disk for processing, which will also greatly improve the work efficiency.

This machine can be widely used in all kinds of minimalist glass doors, sliding doors, swing doors, broken bridge aluminum doors and windows, curtain walls, RV high-speed rail aerospace, tent sun room, cue box and other fields of aluminum processing. It is also possible to customize the model configuration function according to your needs.

◎It is suitable for the processing of industrial aluminum alloy profiles, round holes, slot holes, lock holes, special-shaped holes, etc., as well as milling, chamfering, and other processes of aluminum profiles.

◎The spindle adopts two high-precision air-cooled electric spindles, with a speed of 6000~18000 rpm, with high precision and good safety. High reliability.

◎ The system adopts CNC numerical control, Shenzhen Kunlun Tongtai CNC systemEquipped with professional graphics library, profile library, support code scanning processing, CAD graphics import processing. The operation is simple and efficient.

◎The cutter adopts a system-controlled spray cooling device.

◎The main components of the machine tool are made of steel structure, and all of them have been vibrated and agedStress relief treatment to ensure the stable operation of the machine tool

◎The X-axis, Y-axis and Z-axis are driven by rack and screw, which has stable transmission and high precision.

◎Three-axis full servo motor, truly realize the efficient and stable three-axis linkage.

◎The worktable is flipped 180°, -90°~0°~+90°, and the profile can be clamped on three sides at one time.

◎The main components of the machine tool are made of steel structure, and all of them have been vibrated and agedStress relief treatment to ensure the stable operation of the machine tool

double-head CNC drilling and milling machine

This is a 3500 large-scale automatic CNC drilling and milling machine specializing in processing various aluminum materials, which has been put into the market for 7 years and is deeply trusted and praised by the majority of users. This machine is a heavy-duty machine, and the machine is designed with a heavy-duty bed, rather than an inferior light machine on the market. The machine body is designed with heavy-duty thickened steel structure, and the bed is finished by large-scale gantry boring and milling, which effectively ensures the stability and precision of the whole plate of the machine, and the machine can still maintain stability and high precision after many years of use.

All electrical components of this machine are all used first-line brands, XYZ three-axis is a pure servo motor, the machine can be kept silent when running, the maximum processing speed of this machine is as high as 20000R, which is 3-5 times that of ordinary CNC drilling and milling machine. The machine is divided into two configurations: the material can be automatically flipped on three sides and without the automatic flip function, and you can choose according to your needs. The machine is equipped with genuine Honghai/Qinglan CNC operating system, both of which are authoritative operating systems for drilling and milling machine tools, and the system is equipped with a multi-Chinese operation interface and one-key switching. The system has hundreds of built-in processing drawing programs, touch selection, even if the operator has no experience in using the machine tool or no education level, it can still be operated within 2 hours and proficient in application within 48 hours. When using, you only need to call the program directly according to your own workpiece requirements, such as 20 minimalist glass doors, Bologna, Weifa, laminate lights, sliding doors, swing doors, sliding doors, various keyholes, corner code holes, broken bridge doors and windows, and dozens of common patterns. In addition to the built-in drawing program of the system, the machine can also be CAD map processing, you can import the CAD drawing path or the path saved by the order splitting software directly into the machine through the USB disk for processing, which will also greatly improve the work efficiency.

This machine can be widely used in all kinds of minimalist glass doors, sliding doors, swing doors, broken bridge aluminum doors and windows, curtain walls, RV high-speed rail aerospace, tent sun room, cue box and other fields of aluminum processing. It is also possible to customize the model configuration function according to your needs.